logo

logo

Process

- 홈

- Process

- Production Process

Ganjang

(Soysauce)

Gochujang

(Red Pepper Paste)

Doenjang

(Soybean Paste)

Plum syrup

Stir Fried

Gochujang

Gourmet Jam

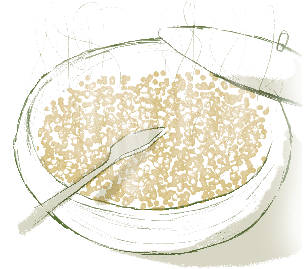

Step1

Harvest well-ripened soybeans 100% from Korea,

Harvest well-ripened soybeans 100% from Korea,

then screen to remove any rotten soybeans.

Step2

Following a traditional recipe,

Following a traditional recipe,

mix steamed soybeans with water

(twice the volume of the soybeans) in an iron cauldron,

then cook slowly.

Stir the cauldron to prevent soybeans sticking to the bottom.

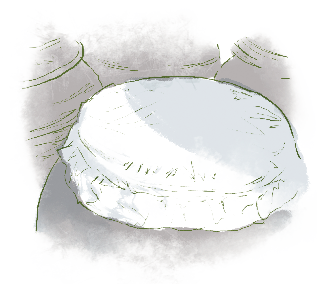

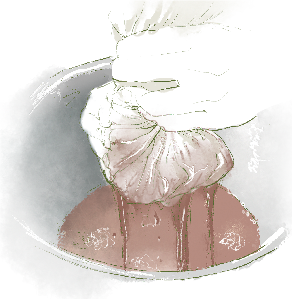

Step3

Once the soybeans are sufficiently steamed,

Once the soybeans are sufficiently steamed,

scoop them up and mash

the beans roughly into a paste.

Use a mold to make the paste into blocks.

Then, place the blocks in a well-ventilated spot,

and leave them to dry at room temperature.

Step4

Once the soybean lumps become dry enough,

Once the soybean lumps become dry enough,

tie them together with straws,

then hang the lumps for

fermentation in a fermenting room.

Here, the temperature and humidity

must be kept around 40Co and 30% respectively.

Step5

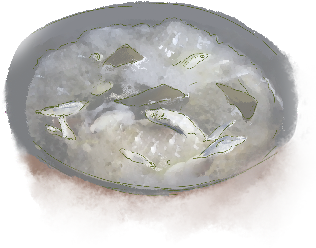

Add sun-dried salt from Sinan to pristine water

Add sun-dried salt from Sinan to pristine water

from Jangheung to prepare an 18% brine solution

that does not require the removal of any bittern.

Soak the evenly fermented soybean blocks in the brine solution.

Place the soybean blocks and brine solution in a ceramic pot,

and anchor the blocks down to prevent them

from rising up to the surface.

Finally, add charcoal. Take extra care for 60~70 days

to make sure no contaminants get mixed into the pot.

Leave the ingredients to mature and ferment

under the clear sunshine and clean winds of Jangheung.

Step6

Once the fermenting period is over,

Once the fermenting period is over,

take out the fermented soybean lumps soaked

in the brine solution.

Then, mash them into a paste again by hand.

Here, add brine to adjust the density of the paste.

Step7

Add kelp from Wando Island,

Add kelp from Wando Island,

black beans produced in Korea,

and shitake mushrooms from Jangheung

to the brine solution,

then simmer for a full day.

Step8

Once the Ganjang has simmered for a full day,

Once the Ganjang has simmered for a full day,

filter with a cloth, pour the Ganjang into a ceramic pot

produced at Gangjin Kiln

(a kiln used to produce Goryeo Celadon),

then leave it under the sun and wind for 720 days.

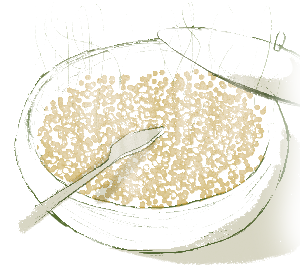

Step1

Ground up fermented soybeans

Ground up fermented soybeans

(100% harvested in Korea),

then sift the powder using a sifter.

Step2

Prepare a 1:1 mixture of sticky rice powder

Prepare a 1:1 mixture of sticky rice powder

(100% harvested in Korea)

and barley malt (100% produced in Korea)

Step3

Ripen red peppers (100% harvested in Korea)

Ripen red peppers (100% harvested in Korea)

for one day, dry them in the sun, remove the stems,

wipe them clean of any contaminants,

then ground them into a fine powder.

Step4

Mix the red pepper powder

Mix the red pepper powder

with the sticky rice powder,

and the filtered plum concentrate,

including the ground up meat of the plum fruit.

Step5

Filter plum concentrate produced

Filter plum concentrate produced

during last year’s summer season

through a cotton cloth, then ground up

the remaining meat of the fruit.

Step6

Mix all ingredients thoroughly,

Mix all ingredients thoroughly,

insert the entire mix into a ceramic pot made

at the Gangjin Kiln, then leave the pot

to let the ingredients ferment

under the sun and in the wind.

Step1

Harvest well-ripened soybeans 100% from Korea,

Harvest well-ripened soybeans 100% from Korea,

then screen to remove any rotten soybeans.

Step2

Following a traditional recipe,

Following a traditional recipe,

mix steamed soybeans with water (twice the volume of the soybeans)

in an iron cauldron, then cook slowly.

Stir the cauldron to prevent soybeans sticking to the bottom.

Step3

Once the soybeans are sufficiently steamed,

Once the soybeans are sufficiently steamed,

scoop them up and mash the beans roughly into a paste.

Use a mold to make the paste into lumps.

Then, place the lumps in a well-ventilated spot,

and leave them to dry at room temperature.

Step4

Once the soybean lumps become dry enough,

tie them together with straws,

then hang the lumps for fermentation

in a fermenting room. Here, the temperature

and humidity must be kept

around 40Co and 30% respectively.

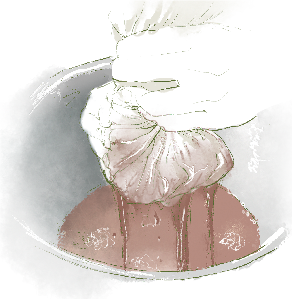

Step5

Add sun-dried salt from Sinan

Add sun-dried salt from Sinan

to pristine water from Jangheung

to prepare an 18% brine solution

that does not require the removal

of any bittern.

Soak the evenly fermented soybean lumps

in the brine solution.

Place the soybean lumps and brine solution in a ceramic pot,

and anchor the lumps down to prevent them from rising up to the surface.

Finally, add charcoal.

Take extra care for 60~70 days to make sure no contaminants get mixed into the pot.

Leave the ingredients to mature

and ferment under the bright sunshine and clean winds of Jangheung.

Step6

Once the fermenting period is over,

Once the fermenting period is over,

take out the fermented soybean lumps soaked

in the brine solution.

Then, mash them into a paste again by hand.

Here, add brine to adjust the density of the paste.

Step7

Prepare a sterile pot, insert the paste

Prepare a sterile pot, insert the paste

(texture must be somewhat thick).

Pack the pot tight to remove any air bubbles

or air pockets inside, sprinkle some Sinan sun-dried salt

and add kelp to further ferment the paste.

Step1

Select plums with small seeds, solid flesh,

Select plums with small seeds, solid flesh,

and without any scarring on the surface.

Remove the stems, clean the fruits with baking soda

and running water, then dry.

Step2

Prepare a sterile pot, insert the green plums

Prepare a sterile pot, insert the green plums

and brown sugar (60:40),

and distribute the ingredients evenly.

Step3

Cover the lid of the pot with a hemp cloth,

Cover the lid of the pot with a hemp cloth,

tie the cloth tight, then place the pot under direct sunlight

for three~four hours a day for a period of three months.

Step4

Once this primary maturing process is complete,

Once this primary maturing process is complete,

remove the plums, pour the plum concentrate into a separate pot,

then ferment it for at least one more year (secondary maturing process).

Step1

Ground up fermented soybeans

Ground up fermented soybeans

(100% harvested in Korea),

then sift the powder using a sifter.

Step2

Mix the red pepper powder

Mix the red pepper powder

with the sticky rice powder,

and the filtered plum concentrate,

including the ground up meat of the plum fruit.

Step3

Prepare a 1:1 mixture of sticky rice powder

Prepare a 1:1 mixture of sticky rice powder

(100% harvested in Korea)

and barley malt (100% produced in Korea)

Step4

Mix all ingredients thoroughly,

Mix all ingredients thoroughly,

insert the entire mix into a ceramic pot

made at the Gangjin Kiln,

then leave the pot to let the ingredients ferment

under the sun and in the wind.

Step5

Ripen red peppers (100% harvested in Korea)

Ripen red peppers (100% harvested in Korea)

for one day, dry them in the sun, remove the stems,

wipe them clean of any contaminants,

then ground them into a fine powder.

Step6

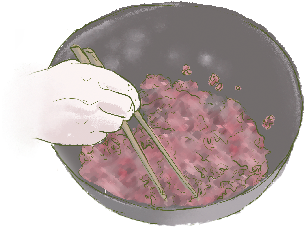

Mince the carefully selected

Mince the carefully selected

ingredients and stir fry.

Step7

Filter plum concentrate produced

Filter plum concentrate produced

during last year’s summer season through

a cotton cloth, then ground up

the remaining meat of the fruit.

Step8

Create a broth with kelp from Wando Island,

Create a broth with kelp from Wando Island,

beef (Korean beef), and fish stock

(dried pollack, anchovies, dried yellow croaker, etc.).

Step9

Mix the matured Gochujang, the broth,

Mix the matured Gochujang, the broth,

and other stir fried ingredients,

then stir fry them once again to add a savory flavor.

Put the final touches on the tasty stir fried Gochujang

by adding some perilla and sesame seed oil.

Step1

Select good-quality fruit, clean them,

Select good-quality fruit, clean them,

and remove any residual moisture.

Step2

Marinate the good-quality fruit

Marinate the good-quality fruit

in organic sugar

and allow the fruit to mature

for approximately a month.

Step3

Meanwhile, slice the fruit into small pieces,

Meanwhile, slice the fruit into small pieces,

then dry them in a heater at 60oC

to minimize the loss of nutrients

while maintaining the chewy texture of the fruit.

Step4

Take out the fruit from the sugar,

Take out the fruit from the sugar,

then add oligosaccharide as well as

the dried fruit and simmer the mixture.

Here, stir the ingredients to make sure

they do not stick to the bottom.

“Fromwell” (hereinafter referred to as the “Company”) values the personal information of its customers. It complies with provisions stipulated in the Act on Promotion of Information and Communications Network Utilization and Information Protection, etc.

Pursuant to its Privacy Policy, the Company shall notify customers on why it collects personal information, how it uses personal information, and what measures it takes to protect personal information.

Collected Personal Information Items

The Company collects the following personal information for online chat (consultation), etc. services.

ο Collected Items: Name, phone number, e-mail

ο Personal Information Collection Method: Official website (online chat), written template

Purpose of Collecting and Utilizing Personal Information Fromwell collects personal information to send product information and to provide more accurate answers to your online inquiries.

Retention and Utilization Period for Personal Information The Company shall destroy personal information immediately when it attains the purpose of collecting and utilizing the corresponding information.

Disposal Procedure and Method for Personal Information. In principle, the Company shall destroy personal information immediately when it attains the purpose of collecting and utilizing the corresponding information. Disposal procedure and method shall be as follows:

ο Disposal Procedure

Information provided for online chats (consultation), etc., shall be transferred to a separate DB once the purpose of

collecting the corresponding information has been attained (paper documents shall be stored in a separate filing cabinet). Then, in compliance

with information protection provisions in internal policies and other relevant legislations, the information is stored for a specific period

(refer to retention and utilization period), and then permanently deleted.

Unless otherwise stipulated by law, information transferred to a separate DB shall not be used for purposes other than the intended purpose prescribed for the information.

ο Disposal Method

- Personal information stored in electronic files shall be deleted using technical methods that render the data

unrecoverable.

Provision of Personal Information

In principle, the Company shall not provide a user’s personal information to an external party. However, exceptions may be made for the

following cases:

- The user previously gave his/her consent to the provision of information

- Required by law, or requested by an investigating

organization for investigative purposes in compliance with relevant legislations.

Outsourcing of Collected Personal Information The Company shall not outsource a customer’s information to an external company without the consent of the customer. If the need to outsource information arises moving forward, the Company shall notify customers of the outsourcing company and details of outsourced tasks, and acquire approval in advance.

Customer Complaints Services regarding Personal Information The Company nominates the following department and person in charge of the management of personal information in order to protect the personal information of its customers, and to facilitate the handling of customer complaints regarding personal information.

Customer Service Department :OOO

Phone No. : OO-OOOO-OOOO

E-mail : OOOOO@OOOO

Name of Personal Information Manager : OOO

Phone No. : OO-OOOO-OOOO

E-mail : OOOOO@OOOO

You can report all complaints pertaining to the protection of personal information that may arise during the course of using our Company’s services to the department or person in charge of the management of personal information. The Company will get back to you with a sufficient answer to your report as quickly as possible.

If you would like to report or request counseling for other violations of personal information, please contact the following organizations:

1.Personal Information Dispute Mediation Committee (www.1336.or.kr/1336)

2.ePrivacy i-Safe Mark Committee (www.eprivacy.or.kr/02-580-0533~4)

3.Cyber Crimes Investigation Center, Supreme Prosecutors’ Office (http://icic.sppo.go.kr/02-3480-3600)

4.Cyber Terrorism Response Center, National Police Agency (www.ctrc.go.kr/02-392-0330)